The magic of the forge.

The manufacture of metal was most likely one of the most important steps in the development of modern humanity. When iron was made and eventually refined to steel it gave us a material that was both very strong and durable. Perfect for both tools, weapons and also armor and there were immense advantages with the new material. It would get a very good cutting edge that you could resharpen and it would stay true even if it was bent during use. It could be forged and hardened and it could be used to make many different things, from thin wires that could be used to make maille armor or buckles for belts and clothing, all the way up to the magnificent Bidenhander, the huge greatswords that the Landsknecht, elites among mercenaries, wielded in the 16th century. Today we use steel for almost every building project, transportation and much, much more.

Knives have always been one of the most versitile and important tools that people had and needed for their survival. Even today it is one of those tools most people can’t be without. For cooking, cutting, working, almost every day will we need a knife. Knives made from iron and later steel were much more durable than the ones made from stone, copper or bronze and could be made as sharp as the razor edged obsidian or flint knives.

Some theory:

I will not bore you with deep information about exactly what happens in the steel but through the hammering, shaping and heating of the steel the composition is changed and whe hot steel is rapidly cooled down, it will change from soft material (austenite) to the very hard chrystalline material martensite. Then the knife must be tempered, the hardness reduced and the flexibility increased. Otherwise you would get a very hard tool that would easily brake. A well hardened and tempered blade will be flexible and have a hard edge that will stay sharp when used properly. Most of the knives made today are made by huge factories that mass produce their wares. This is efficient and lowers the costs for production and the tools made can be made to good quality. Of course there are also poor quality knives made today and not everyone wants something made by machines.

For that reason, there are knife makers that have gone back to the basics and started making knives by hand again. I am one of those.

Many who make knives today grind out their knives from bar stock and send them off for tempering. This can be an effective way to make knives of high quality but is not for me. The quality made by these makers is absolutely superb and their method is in no way inferior to forging, but the modern way simply is not for me so much. For me that handmade feeling is more important than automatic tempering kilns, grinding jigs and all that.

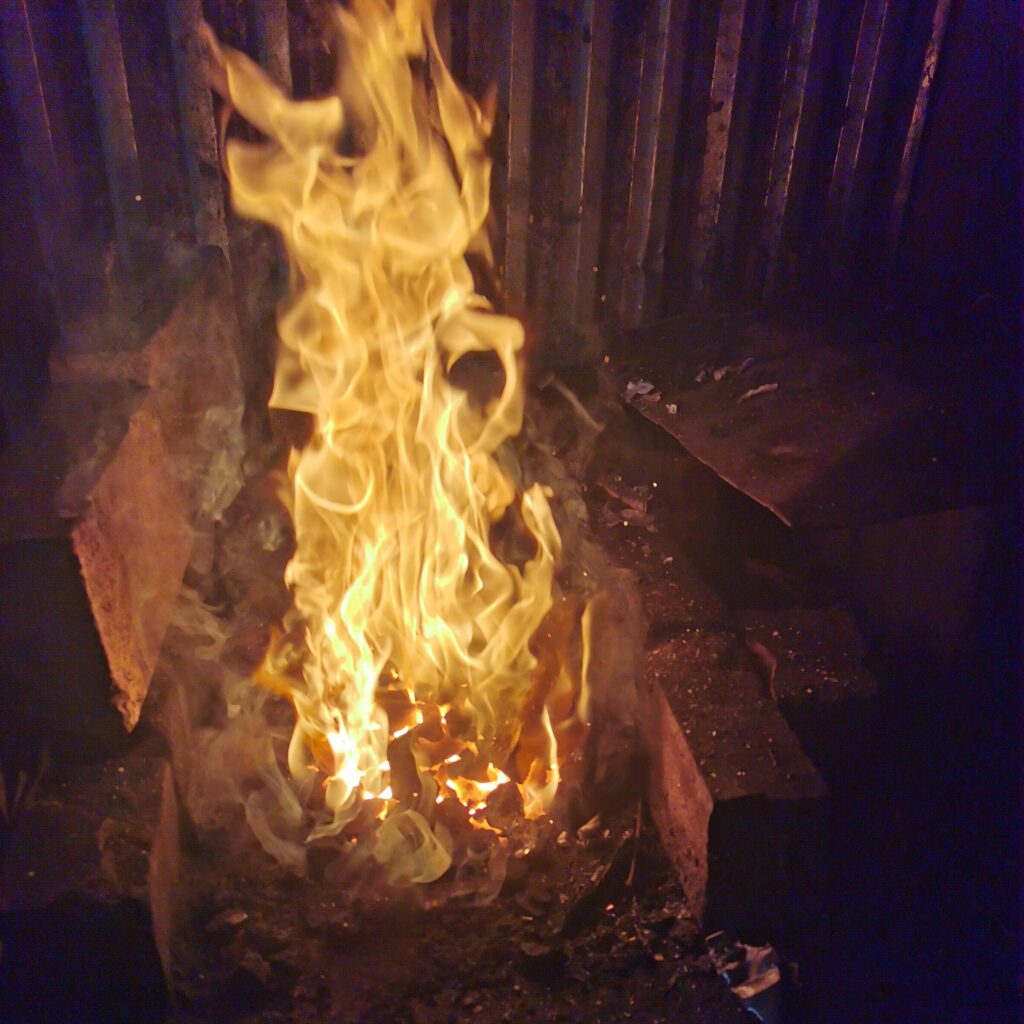

Differently from many hand made knives today, I still forge my knives in a coal fire and I harden and temper them myself. In my forge, the metal is heated, then hammered out by hand on the anvil and then free hand ground on the bench or belt grinder, hand finished and then the handles are made by hand from high quality materials. I mostly make historically inspired blades and feel a deep satisfaction to make them close to the originals. The knives are all hand finished and then sharpened.

Then the sheaths are made by hand from high quality leather and/or wood.The magic that happens in the forge, where the hard and unforgiving steel is shaped to a beautiful knife, is to me a way to meditate, to archive inner peace and to create art.I hope you can also appreciate the hard work and dedication, the small pieces of my soul that are impregnated in all of my knives. Feel free to contact me for more information, make a request and talk to me about your wishes, maybe you will also have a chance to have that beautiful, handmade high quality knife in your belt. I guarantee that it was made with high quality and with great care.

No knife is indestructible, but I test all my work before sending it out, both in chopping wood, copper pipe, antler/bone, as well as batoning them through steel rods and nails.I want to guarantee the best knife I can make and should you not be happy, I will be open to talk about the problem and in the cases where I perhaps made a mistake will make another knife for you.Where the magic happens.